Lifting heavy objects is hard work, but preparing for the lift can take significantly more time than the lift itself. In addition to the lift plan that we create for every job, big lifts require travel permits and detailed route planning just to get to the job site.

Once we arrive, the mobile crane setup procedure can take hours even if the lift itself will only take a few minutes. During the setup, we’ll have as many as 12 crew members working together to ensure the lift can proceed safely.

For some jobs, actually lifting and placing loads only accounts for 5% of what we do. Even for relatively small projects, “hook time,” the time we’re actively lifting, might amount to 25% of our job. To give you a better idea of what it takes to get your project off the ground, let’s discuss the on- and off-site site work we do to make sure we can complete your lift as scheduled.

Creating a Plan

Anyone who’s played the crane game at an arcade knows how important it is to plan out every little move. You can kiss your quarter goodbye if the claw’s arms so much as brush against the stuffed penguin next to the teddy bear you’re after.

Now imagine that the penguin in your way is a skyscraper or a row of power lines. Brushing against it with a heavy load will cost a heck of a lot more than a quarter. In addition to monetary damages, it could cost someone their life. To prevent these kinds of disasters, we create meticulous lift plans for every lift we perform.

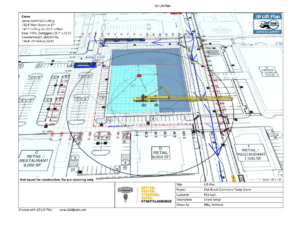

When making a lift plan, we start by mapping out the job site as well as all of its surroundings. With the stage set, we figure out where we’ll have room to assemble the crane, factoring in space for any support vehicles we might need. Next, we plan out every move the crane will need to complete the job.

For some lifts, like those in Chicago’s Loop, we also need to perform a crane placement survey. In these cases, we use ground-penetrating radar to locate any subterranean voids, like sewers or subways. This allows us to determine the structural stability of the site, ensuring that the ground will support the crane under its full load.

There’s no margin for error when it comes to crane safety. So we double-check every detail of our plans before we ever head out to perform a lift. This attention to detail has helped us win back-to-back awards for 3D Lift Plan of the Year. But even the most intricate lift plan will go to waste if you can’t get the crane to the construction site.

Travel Planning

Although mobile cranes are street-legal vehicles, we can’t just hop in the driver’s seat and ask our phone’s GPS for directions to the job site. Because of their height and weight, we need to carefully plan every turn from our facility to the lift location. And the bigger the crane is, the more restrictions we’ll need to consider when planning our route.

Telehandlers and truck cranes are small enough to go almost anywhere that a normal passenger vehicle can go. But even when the crane is fully retracted on our smallest truck crane, the vehicle still towers more than 12 feet into the air. And it weighs in at 56,000 lbs, which is roughly equivalent to 10 Chevy Suburbans.

Thus, there are some roads and bridges that we simply can’t use. Even if we have to travel an extra hundred miles to avoid them, we don’t have any other options. A trip that would take you 30 minutes in a sedan could take two and a half hours in a mobile crane. And if we haven’t precisely planned our path in advance, we could get within a mile of the job site before realizing we need to reroute.

Vehicles that weigh 40 tons or more also require travel permits. So part of the travel planning process for mobile cranes involves reaching out to the Illinois Department of Transportation and local municipalities for permission to use their roads. We might have to travel through more than a dozen municipalities to get to a job site, and getting permits from each of them takes time.

Between planning a route, securing permits, and actually driving from point A to B, travel time and planning account for a sizable portion of the cost to rent a crane. And once we get to the job site, there’s still plenty of work to do before we can start lifting.

The On-Site Mobile Crane Setup Procedure

When we roll onto a job site, the crane operator gets started by moving the crane into position. The operator needs to carefully align the crane in the location identified in the lift plan. Once in place, they will extend the outriggers for stability and secure the crane on the outrigger mast.

Then, our support vehicles will approach with the counterweights. The largest lifts might need as much as 352,000 lbs of counterweights, which translates to eight flatbed trucks worth of weights. In a wide-open area that allows all of the trucks to approach simultaneously, this process might only take 20 minutes per truck. On a busy city street, it can take hours.

If the lift requires a luffing jib, that, too, will need to be brought to the site on a truck of its own. And sometimes attaching the jib to the crane will require a second, smaller crane, commonly called the Assist Crane. Once the jib is assembled and attached, we’ll swing it into position. Then, finally, the crane is “hook ready,” meaning we can start lifting!

The lifting part of the job often takes a fraction of the time to set up the crane when we only need to move a single item. But some jobs require dozens of different lifts. And the more lifts a job requires, the more time we spend securing loads to the hook, which we refer to as rigging time.

Different loads often require different rigging plans. Some loads need four straps, others need six. Some require spreader bars, lifting beams, or different shackles sizes. Every rigging change takes time but is an essential part of performing a safe crane lift.

Once we complete the last lift, we go through the whole mobile crane setup procedure again in reverse. We remove the luffer and secure it to its transport truck. Then the counterweight trucks file in, collect their weights, and file out. We suck in the boom, retract the outriggers, and make our way back home, following our carefully planned route to do so.

Let Us Help You Prepare for Your Next Lift

The above information should give you a better understanding of the extensive work that goes into every lift. It should also reinforce how important it is to discuss every detail about your site and the lift you need performed. If you don’t acknowledge every obstacle and plan accordingly, the lift could take hours or even days longer than expected. And the cost for that extra time might complicate your budget.

With more than 50 years of experience, La Grange Crane has become the leading crane rental company in the Chicagoland area. If you have some heavy lifting to do, give us a call at (708) 354-3452 to discuss the project. We’ll guide you through the whole process and make sure your lift goes exactly as planned.